Top Cable carries out numerous tests to ensure the quality of their cables Medium Voltage…

Medium Voltage cable: Design & Construction

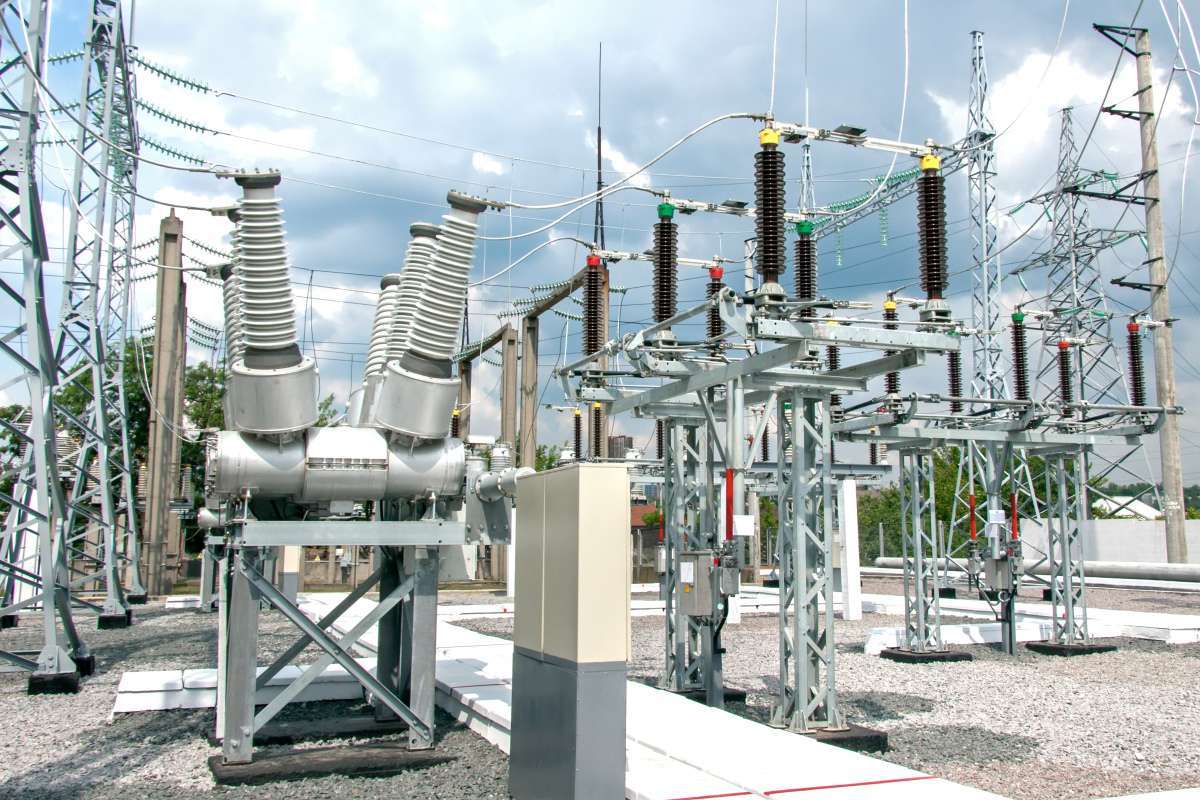

A medium voltage cable is a cable used to distribute electricity from power substations to transformer stations. It has a minimum power rating of 1kV and goes up to 36kV. Top Cable’s entire range of medium voltage cables is designed according to the most demanding international standards. You can consult it all here.

LAYERS OF MATERIALS MAKING UP A MEDIUM VOLTAGE CABLE

The composition and design of medium voltage cables is defined by the following elements or layers:

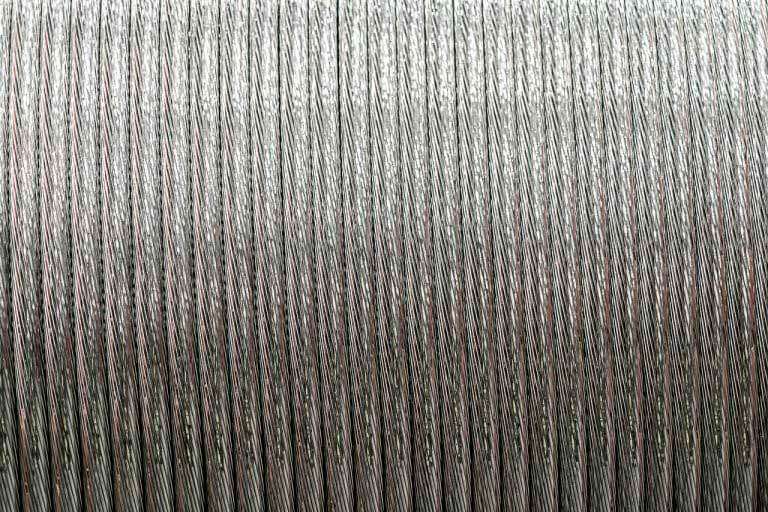

1. CONDUCTOR

It carries the electric current. It is the central element of the cable. The conductors are class 2 and are made of electrolytic copper or high purity electrolytic aluminium.

2. INTERNAL SEMICONDUCTOR SCREEN

It completely covers the conductor. It is made to improve the distribution of the electric field on the surface of the conductor.

3. CABLE INSULATION

Insulation is the critical component of the MV cable, since it has to withstand the high electric field inside. The maximum voltage that a cable can withstand depends on the material and the insulation thickness, which increases with the cable rated voltage. The materials used in the insulation of Medium Voltage cables are as follows:

- Crosslinked polyethylene (XLPE)

- High modulus Ethylene-Propylene (HEPR)

- Ethylene-Propylene (EPR)

4. CABLE EXTERNAL SEMICONDUCTOR

It completely covers the insulation. This material is cross-linked and in perfect contact with the insulation. Peelable semiconductors, partially bonded to the insulation, are usually used to make the preparation of the connections as easy as possible.

5. CABLE METAL SCREEN

Medium voltage cables have a metal screen in contact with the external semiconductor. This screen is made up of copper fibres placed in a helix, uniformly covering the whole perimeter of the cable.

6. PROTECTION AGAINST WATER (ONLY -OL AND -2OL TYPE CABLES)

In cables with a longitudinal seal (type -OL), a tape of hygroscopic material is placed under the sheath, which prevents the longitudinal propagation of water. In cables with Double Sealing, a series of hygroscopic wires are also placed on the conductor (type -2OL).

7. INNER SHEATH (ONLY FOR ARMOURED CABLES)

All armoured cables have a separation cover (or armour pad) between the metal screen and the armour. This inner sheath is made of the same material as the outer sheath.

8. ARMOUR (ONLY FOR ARMOURED CABLES)

Armours improve the protection of the cable against external aggressions. Their use is recommended in all installations where there is a high risk of mechanical aggression. The armour consists of metal wires or strips arranged on the inner sheath. The metal used in single-core cables is aluminium.

9. CABLE OUTER SHEATH

This is the outermost layer of the cable and protects the cable from the mechanical and chemical aggressions. It is formed by a uniform and continuous coating, usually red colour, which is totally watertight and highly resistant to knocks and abrasions, as well as to the action of the weather. The materials normally used are PVC and halogen-free polyolefins.

TOP CABLE, MANUFACTURER AND DISTRIBUTOR OF MEDIUM VOLTAGE CABLE

Top Cable’s Medium Voltage cables are designed according to the most demanding international standards. We manufacture X-VOLT® Medium Voltage Cables: RHZ1 and HEPR. 6/10kV, 8.7/15kV, 12/20kV, 18/30kV, in copper and aluminium.

If you need a medium voltage cable for your project, contact our sales team and find the one that best suits your needs.