In a rooftop solar installations, it is advisable to use ground cables with tinned copper…

The electric cables’ lifespan: how long do cables last?

If you purchase electrical cables manufactured according to International Standards, your cables’ lifespan expected to last at least between 20-30 years. But what could affect the lifespan of an electric cable?

CHOOSING THE RIGHT INSULATION, OUTER SHEATH AND CABLE SIZE

Understanding the factors that influence cables’ lifespan, recognizing the signs that indicate a need for replacement, and knowing how to extend their useful life are essential for maintaining electric safety and efficiency.

The electric cables’ lifespan can be significantly influenced by a multitude of factors, such as the selection -or not- of appropriate insulation and outer sheath. For instance:

- Cables operating in high-temperature environments require insulation materials that can withstand the heat without degrading.

- Cables operating in high-demanding installations may require a rubber outer sheath, instead of an XLPE one.

Ensuring that the cables are correctly sized for the electrical load they will carry is crucial for their longevity. Undersized cables can lead to overheating and insulation failure, while oversized cables may be inefficient and more expensive. You may easily calculate your cable cross-section here.

OPERATIONAL AND ENVIRONMENTAL FACTORS THAT INFLUENCE A CABLES’ LIFESPAN

There are, however, many operational and environmental factors that affect the actual electric cables’ lifespan. These include:

ELECTRICAL FACTORS

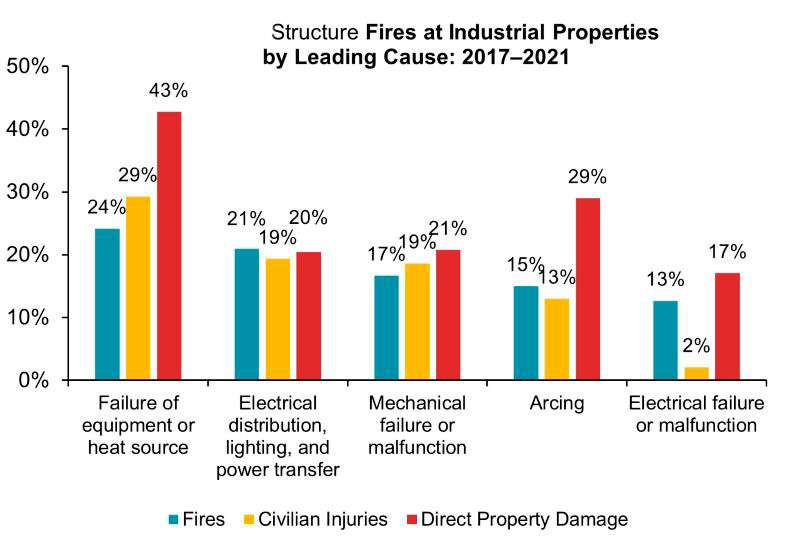

Electrical overload is another major factor that can drastically reduce the electric cables’ lifespan. Operating cables beyond their rated current capacity can cause overheating, which may lead to insulation failure or start a fire. This not only compromises the cable’s integrity but also poses significant safety risks por people and equipment.

TIP: Regular monitoring and maintenance can help prevent overloading and ensure that cables are operating within safe parameters.

THERMAL FACTORS

When purchasing electric cables, it’s crucial to consider the thermal rating specified by the manufacturer. This indicates the minimum and maximum temperature that the cable can safely operate at for a sustained period of time. This rating is determined by the insulation and/or the cable outer sheath. Exceeding this limit can drastically reduce the cable’s lifespan and compromise its insulation properties. Proper cable ventilation and cooling systems can help mitigate the effects of heat, prolonging its service life.

ENVIRONMENTAL FACTORS

Extreme temperatures, whether hot or cold, can cause the insulation to become brittle or melt, leading to failure. Moisture is another enemy of electric cables, as it can corrode the conductors and degrade the insulation. Or if there is an unforeseen rodent attack.

TIP: Understanding the specific environmental conditions in your industrial setting is essential for selecting the right type of cable and implementing protective measures.

CHEMICAL FACTORS

Chemical exposure, such as contact with oils, solvents, or other corrosive substances, can also accelerate the breakdown of cable materials, degrading the cable insulation or outer sheath.

TIP: selecting the right cable outer sheath can prevent from future cable damage.

MECHANICAL FACTORS

Mechanical stress can severely impact the electric cables’ lifespan. Cables that are subject to excessive flexing, vibration, or tension can experience damage to the insulation or conductors. This is particularly relevant in industrial environments where machinery and equipment are in constant motion.

TIP: Ensuring that cables are securely mounted and protected from excessive movement can help mitigate this type of damage.

CABLE INSTALLATION AND TERMINATION

Cables that are not properly installed or terminated can be more susceptible to damage. Poor installation practices can lead to issues such as loose connections, improper grounding, and insufficient strain relief, all of which can shorten the cable’s lifespan.

TIP: Adhering to best practices during installation and termination can significantly enhance the durability and performance of electric cables.

PURCHASING HIGH-PERFORMANCE QUALITY CABLES

When it comes time to purchase electric cables, selecting the best quality cable manufacturer and consulting with cable experts can ensure that your cables are well-suited to your operational environment, optimize safety and efficiency.

If you would like to request a quote for a new project, please do not hesitate to contact us.