In recent years, the use of EMC variable frequency drive motors has been increasing, both…

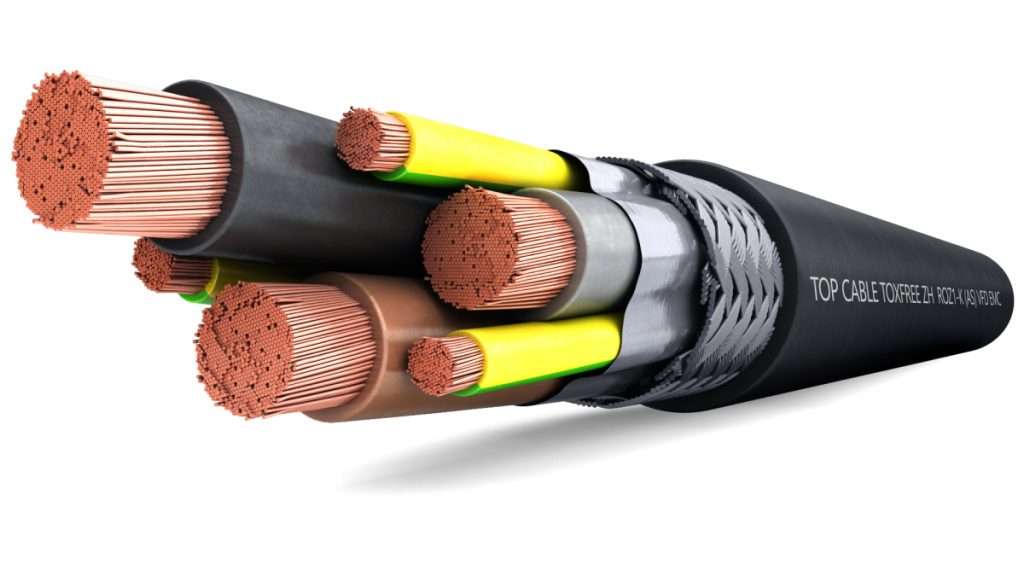

TOPDRIVE® ROZ1-K, the power supply cable for motors with VFD drives

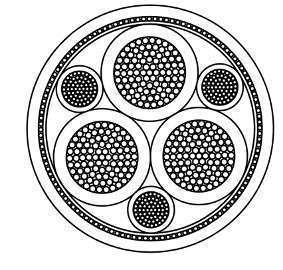

The high performance cables for powering variable frequency drive (VFD) motors feature a symmetrical 3C+3G configuration, double shielding for 100% coverage, and a halogen-free outer sheath, providing maximum system reliability and stability. TOPDRIVE® VFD ROZ1-K cable has been specially designed for industrial VFD installations where it is necessary to limit the effects of Electromagnetic Interference (EMI).

DESIGN:

1 – Flexible copper conductor (class 5).

2 – Protective conductor: the earth conductor is divided into three conductors (3G).

3 – Cross-linked polyethylene insulation (XLPE).

4 – Double shield of overlapping aluminium-polyester tape, plus a braid of tinned copper wires. 100% shielding.

5 – Halogen-free polyolefin (LSZH) outer sheath.

RECOMMENDATIONS FOR SELECTING THE RIGHT VFD CABLE

25% of the world’s electrical energy is consumed by electric motors. Variable frequency drives (VFD) provide better performance and increased energy efficiency for industry but, at the same time, one of their main disadvantages is the emission of electromagnetic interference. To limit interference it is necessary to use equipment and cables with electromagnetic compatibility, known as EMC.

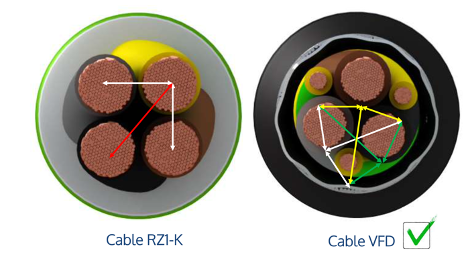

EMC is achieved in an electrical cable by two features: first, through a symmetrical distribution of conductors. Secondly, by adding a shield to ensure protection when using VFD motors.

To improve the performance of the VFD, we therefore recommend:

- Cables with low capacitance and high electrical resistance

- Cables with copper conductors (class 5) with improved flexibility.

- Cables with a grounding system designed for the lowest possible impedance of the ground path. A system of three phase conductors (3C) plus three ground conductors (3G) arranged alternately and symmetrically ensures that potentially damaging common mode current (CMC) is contained and returned to the drive without adverse effects.

- Cables with a low impedance screen for reduced current reflection and increased system reliability. Shielding with a double aluminium-polyester screen plus tinned copper mesh provides the best performance (100% shielding) and prevents corrosion, minimising electromagnetic interference (EMI). Conversely, a cable with an inadequate shield (or no shield) can act as an antenna and be a source of radiated emissions.

- XLPE insulated cables to facilitate maximum electrical performance and avoid the effect of voltage spikes.

- Cables with an oil resistant, UV resistant and halogen free (LSZH) outer sheath in case of fire.

TECHNICAL CHARACTERISTICS OF THE TOPDRIVE® ROZ1-K VFD (EMC) CABLE

If you are looking for a cable for powering motors with variable frequency drives with the highest performance, the TOPDRIVE® ROZ1-K VDF (EMC) cable has been specially designed for use in installations where it is necessary to limit the effects of Electromagnetic Interference (EMI), also known as Radio Frequency Interference (RFI).

Maximum fire performance CPR (Cca)

Flexible cable

Halogen free

Minimum service temperature: -40ºC

INSTALLATIONS WHERE TOPDRIVE® ROZ1-K VFD (EMC) 0,6/1 kV CABLE IS SUGGESTED FOR USE

TOPDRIVE® ROZ1-K VFD (EMC) 0.6/1kV cable is the right cable for fixed installations, motors or variable speed pumps in:

- Robots.

- Conveyors.

- Machines with repetitive or continuous motion.

- Power generation plants.

- Metallurgical industry.

- Petrochemical industry and Gas (Oil & Gas).

- Mines.

- Water treatment.

- Large Air Conditioning systems.

- Cement plants.

- General industry.

WHERE TO BUY TOPDRIVE® ROZ1-K VFD (EMC) FOR FREQUENCY INVERTERS?

To buy TOPDRIVE® ROZ1-K rubber cable on drums in various formats, please see our sales conditions for Electrical Distributors and Wholesalers here. We can also put you in touch with your nearest Top Cable distributor.

Some of the most common cross-sections with immediate stock are as follows:

| Cable | Conductor cross-section (mm2) |

| TOPDRIVE® ROZ1-K VFD (EMC) | 3 x 6 + 3 G 1,5 |

| TOPDRIVE® ROZ1-K VFD (EMC) | 3 x 16 + 3 G 2,5 |

| TOPDRIVE® ROZ1-K VFD (EMC) | 3 x 16 + 3 G 6 |

| TOPDRIVE® ROZ1-K VFD (EMC) | 3 x 50 + 3 G 10 |

| TOPDRIVE® ROZ1-K VFD (EMC) | 3 x 120 + 3 G 16 |

| TOPDRIVE® ROZ1-K VFD (EMC) | 3 x 240 + 3 G 50 |

| TOPDRIVE® ROZ1-K VFD (EMC) | 4 G 2,5 |

If you need to consult additional technical aspects of this cable, such as its maximum admissible current or voltage drop, please contact us.

TOPDRIVE® ROZ1-K

Flexible EMC LSZH screened cable for Variable Frequency Drive motors

FREQUENTLY ASKED QUESTIONS (FAQ) ABOUT TOPDRIVE® ROZ1-K VFD CABLE (EMC)

Are all VFD cables the same and what advantages does the TOPDRIVE® ROZ1-K cable have over other R0Z1-K cables?

Top Cable’ s TOPDRIVE® ROZ1-K cable design is the one with the highest performance, favouring earth leakage and avoiding the effect of voltage peaks:

Flexible copper conductor (class 5), which gives the cable maximum flexibility.

Arrangement of conductors and earth three plus three (3C+3G) to avoid current leakage through earth.

Cross-linked polyethylene insulation (XLPE) with performance far superior to PVC.

Double aluminium-polyester screen that offers 100% shielding and thus prevents the emission of electromagnetic waves from our cable to the rest of the equipment.

Tinned copper mesh, with anti-corrosion features and better installation.

Halogen-free outer sheath (LSZH) with the highest CPR classification (Cca – s1a, d1, a1) with low emission of fumes and corrosive gases in case of fire to protect people and equipment.

This is why Top Cable’s TOPDRIVE® R0Z1-K cable is recommended by leading manufacturers of variable frequency drives and also by GAMBICA, the British Capital Goods Association.

If you are looking for a cable for powering motors with variable frequency drives of the highest performance, please contact us.

Why is it recommended to use XLP cables (as opposed to PVC) to power VFD motors?

To avoid voltage peaks, we should use a cable with XLPE insulation (90ºC) instead of one with PVC insulation (70ºC). In addition, the dielectric coefficient of XLPE (2.3) is much lower than that of PVC (7.4), which also reduces the capacitive effect and therefore the magnitude of the reflected waves.

Can I install an unshielded cable to power motors with VFD drives?

As mentioned above, a cable with an inadequate shield (or no shield) can act as an antenna and be a source of radiated emissions. RV, RV-K, or RZ1-K cables do not guarantee electromagnetic compatibility and impedance matching, and are therefore not suitable for powering VFD motors.

Similarly, it is not advisable to install single core cables, even if they are shielded, as it is necessary to compensate for inductions and respect the symmetrical configuration of the 3C+3G phases.

Where can I find the technical specification of the TOPDRIVE® ROZ1-K cable in PDF format?

Here is the PDF of the summary technical specification of the TOPDRIVE® R0Z1-K cable. If you need to consult additional technical aspects of this cable, such as its maximum admissible current or voltage drop, please contact us.

What is the price of the TOPDRIVE® ROZ1-K rubber cable?

At Top Cable you will get the highest quality cables, with the best prices and the best service for TOPDRIVE® R0Z1-K rubber electrical cable drums and spools. Contact us.

What is the colour code of the TOPDRIVE® ROZ1-K cable?

The standardised identification of the insulated conductors of the TOPDRIVE® R0Z1-K cable is as follows:

3 x + 3 G: Grey + brown + black + Yellow/Green (3G) (from 6 mm2).

4 G : Grey + brown + black + Yellow/Green (up to 4 mm2).

What features does the TOPDRIVE® ROZ1-K cable offer against fire?

Flame non-propagation according to UNE-EN 60332-1 / IEC 60332-1.

Fire non-propagation according to UNE-EN 60332-3 / IEC 60332-3 and EN 50399.

CPR reaction to fire: Cca-s1a, d1, a1, according to EN 50575.

Halogen-free according to UNE-EN 60754-1 / IEC 60754-1.

Low emission of corrosive gases according to UNE-EN 60754-2 / IEC 60754-2.

Low smoke emission according to UNE-EN 61034 / IEC 61034:

Light transmittance > 80%.

What certifications does the TOPDRIVE® ROZ1-K cable meet? What is its CPR rating? Where can I check its DoP?

TOPDRIVE® R0Z1-K cable has been designed according to the IEC 60502-1 / IEC 60092-353 reference standard and complies with the European CPR (Construction Products Regulation) Cca – s1a, d1, a1. You can consult the Declaration of Performance (DoP) at this link. In addition, the TOPDRIVE® R0Z1-K cable is CE / UKCA / BUREAU VERITAS / DNV-GL / ABS /LLOYD’S REGISTER / RoHS /.

What precautions should be taken into account during the installation of a TOPDRIVE® ROZ1-K cable for VFD applications?

Certain precautions must be taken during installation:

Always respect the bending radius of the cable. Radii smaller than the minimum indicated may cause damage or breakage to the outer sheath.

Adequacy of the laying. The cable must be laid carefully, taking care not to damage the cover in irregular areas, sharp edges, etc.

Fixings/Fastenings. Adapt the fixings so that the cable adopts a natural position in the laying to avoid stress concentration on the roof. Allow a certain degree of freedom of movement and avoid excessively tight cable ties.

How does a variable frequency drive (VFD) work?

A Variable Frequency Drive (VFD) is a system for controlling the rotational speed of an alternating current (AC) motor by controlling the power frequency supplied to the motor.

An electric motor rotates its rotor according to the parameters achieved by the voltage and frequency of the electrical power supplied to the motor. Internationally, there are different mains voltages, such as 400 V (three-phase), 380 V (three-phase), etc., and frequencies of 50 or 60 Hertz. By varying the voltage and/or frequency, the performance of the motor, including the speed, varies. It is usually difficult to change the voltage or frequency without auxiliary equipment.

To vary the voltage and frequency effectively, a variable frequency drive is used. Normal power is supplied to the VFD and the output of the VFD is fed to the electric motor. The VFD has controls that can be adjusted to control the speed of the motor.

A VFD provides precise control of the speed and torque of an AC motor through pulse width modulation (PWM). In a VFD system, it is critical to choose the right cable for best performance, maximum energy efficiency and long life.